Sim racing has evolved significantly over the years, not just in terms of graphics and gameplay but also in the technology that drives the experience.

One crucial aspect that often defines the performance of a sim racing setup is the wheelbase technology.

Table of Contents

- Gear-Driven Wheelbases: A Classic Approach

- Gears as the Backbone of Traditional Sim Racing

- Drawbacks of Gear-Driven Systems

- Modern Applications of Gear-Driven Technology

- Belt Wheelbase Tech: Smoothing Out the Experience

- Transition from Gears to Belts

- Prominent Examples in the Market

- Downsides of Belt-Driven Technology

- Hybrid Systems: Bridging the Gap

- Combining Gears and Belts for Optimal Performance

- Challenges Persisting in Hybrid Designs

- Sim Racing Direct Drive: Pinnacle of Performance

- Revolutionizing Force Feedback with Direct Drive

- Unparalleled Detail and Maintenance Advantages

- Affordability and Accessibility of Direct Drive

- Belts, Gears, or Direct Drive? Making an Informed Choice

- Direct Drive: The Future of Sim Racing

- Merits of Lesser Products

- Platform Compatibility and Usability

Gear-Driven Wheelbases: A Classic Approach

Gears as the Backbone of Traditional Sim Racing

The roots of sim racing wheelbase technology trace back to the utilization of gear-driven systems.

In this classic approach, a series of gears function as intermediaries, transferring torque from the Force Feedback motor to the racing wheel.

The fundamental advantage of this system lies in its capability to significantly amplify the power output of a relatively low-energy motor. This amplification translates into commendable Force Feedback, allowing players to feel the nuances of the virtual racing environment.

Drawbacks of Gear-Driven Systems

However, the gear-driven approach is not without its drawbacks. One prominent issue is the introduction of vagueness in the steering feel due to the presence of multiple gears. Small deadzones in the steering lock often occur, attributed to the slight play between each gear’s teeth. Additionally, the engagement of gear teeth leads to clunking sounds, reminiscent of older setups that required finesse to navigate without disturbing the household.

Modern Applications of Gear-Driven Technology

While gear-driven wheelbases are considered somewhat outdated, they remain prevalent in entry-level wheels due to their affordability. Examples such as the Thrustmaster T128 and the Logitech G27, G29, G920, and G923 series exemplify gear-driven wheelbases that cater to the needs of beginners in the sim racing community.

Belt Wheelbase Tech: Smoothing Out the Experience

Transition from Gears to Belts

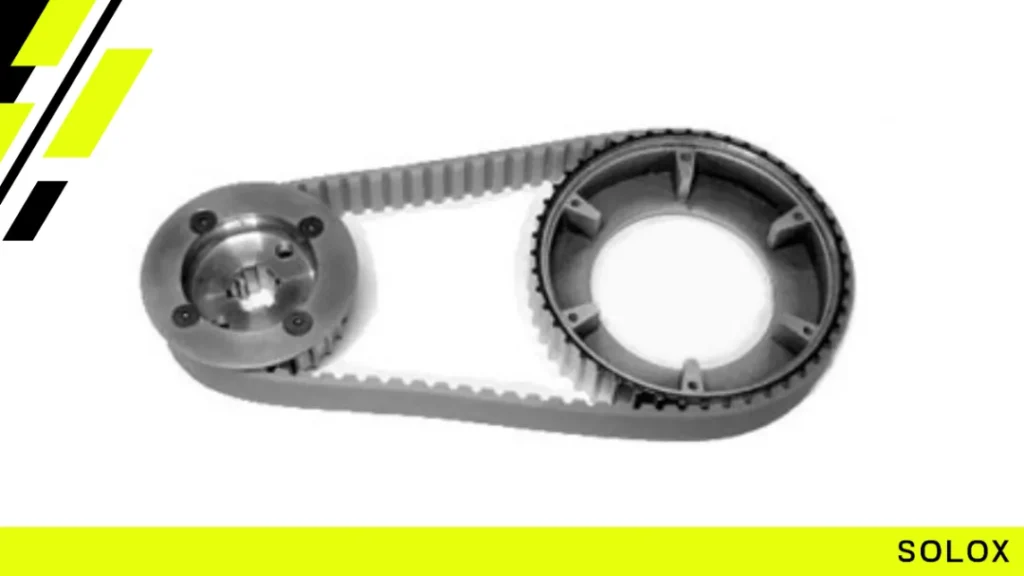

The early 2010s marked a significant shift in sim racing wheelbase technology with the introduction of belt-driven systems. In contrast to the clunky nature of gear-driven wheels, manufacturers began experimenting with rubber belts to enhance the overall racing experience. The transition aimed to create a smoother rotation of the wheel, eliminating the deadzones and intrusive sounds associated with gear-driven setups.

Prominent Examples in the Market

Although no longer on sale, Fanatec’s CSW 2.5 stands out as a notable example of belt-driven wheelbase technology. In the contemporary market, Thrustmaster has become a prominent player in the realm of belt-driven wheelbases, with its T-GT II model showcasing the advancements in this design.

Downsides of Belt-Driven Technology

However, the adoption of belts introduces its own set of challenges. The rubber design of belts may lead to stretching under high loads, resulting in a loss of tactile feedback. High-frequency details, such as road bumps and subtle corrections, might get overshadowed in the overall experience. Moreover, extended use may cause belts to snap, necessitating replacements and potential disruptions to the racing session.

Hybrid Systems: Bridging the Gap

Combining Gears and Belts for Optimal Performance

Recent years have witnessed the emergence of hybrid systems, blending the strengths of both gears and belts to address the limitations of each design. In this hybrid approach, the majority of the motor’s force is transmitted through the belt during regular rotations. However, when encountering high-frequency jolts or bumps in the virtual terrain, gears come into play to enhance the fidelity of Force Feedback.

Challenges Persisting in Hybrid Designs

Despite the attempt to create a seamless integration of gear and belt technologies, the distinctive clunking sound associated with gears remains present in hybrid systems. Manufacturers, recognizing the waning popularity of pure gear-driven designs, have shifted towards incorporating hybrid technology in their entry-level offerings. Thrustmaster’s T248 exemplifies the successful implementation of hybrid sim racing wheelbase technology, providing users with a balanced and nuanced racing experience.

Sim Racing Direct Drive: Pinnacle of Performance

Revolutionizing Force Feedback with Direct Drive

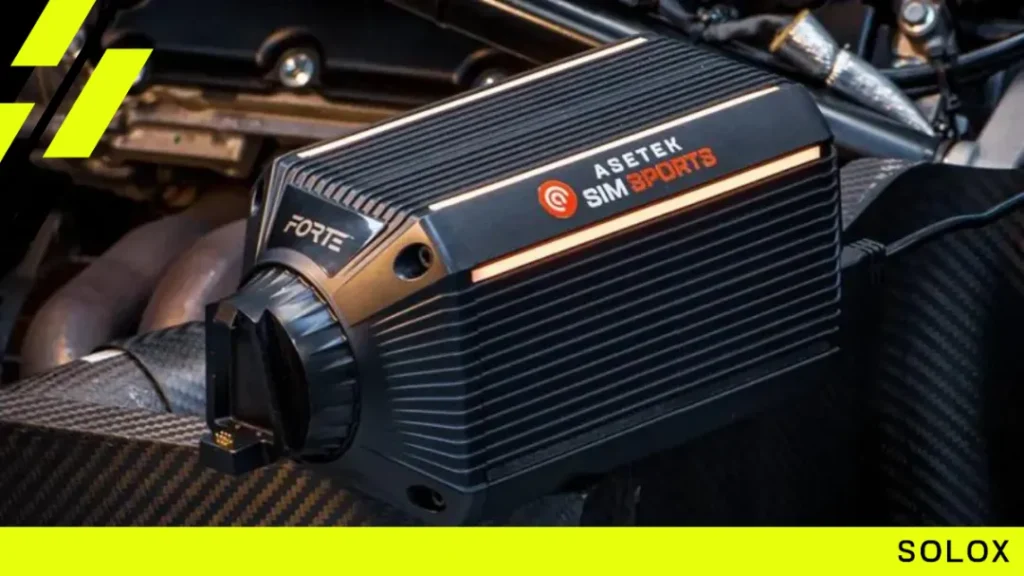

The mid-2010s marked a paradigm shift in sim racing wheelbase technology with the introduction of Direct Drive systems. Unlike their predecessors, Direct Drive wheelbases no longer grapple with the challenge of amplifying power from a smaller motor. Instead, these systems accommodate larger, more powerful motors that transmit force directly into the racing wheel, hence the name ‘Direct Drive.’

Unparalleled Detail and Maintenance Advantages

Direct Drive technology revolutionizes Force Feedback, offering unparalleled detail and responsiveness. With no gears introducing deadzones or belts to stretch, the loss of detail is virtually nonexistent. Moreover, the absence of additional moving parts in Direct Drive wheelbases translates to minimal maintenance requirements. These systems are known for their durability, with the ability to run almost indefinitely. However, users should be mindful of potential cooling issues with the larger electric motors, necessitating periodic breaks during extended usage.

Affordability and Accessibility of Direct Drive

While Direct Drive wheelbases initially gained a reputation as exclusive premium products due to their higher costs, recent developments have shattered this perception. Entry-level Direct Drive options from manufacturers like MOZA Racing and an expanding selection of premium products from Asetek and Fanatec showcase the increasing accessibility of Direct Drive technology across different price points.

Belts, Gears, or Direct Drive? Making an Informed Choice

Direct Drive: The Future of Sim Racing

In the grand landscape of sim racing wheelbase technology, Direct Drive undoubtedly stands out as the future. The unmatched detail in Force Feedback, modularity, and the expanding range of products available make Direct Drive wheelbases the go-to choice for serious sim racers.

Merits of Lesser Products

However, there is still merit in considering lesser products, especially for those new to the hobby or seeking a more budget-friendly option. Belt-driven wheelbases, despite their drawbacks, offer a fantastic means of experiencing Force Feedback. They remain a practical choice for individuals unsure of their long-term commitment to sim racing or for younger enthusiasts taking their first steps into the virtual racing world.

Platform Compatibility and Usability

Another factor influencing the choice of wheelbase technology is platform compatibility. While Direct Drive wheels excel in performance, their compatibility with consoles is limited. For those seeking a versatile solution usable across multiple platforms, exploring the possibilities offered by gear-driven or belt-driven wheelbases becomes essential.

In conclusion, the world of sim racing wheelbases is diverse, catering to a wide range of preferences and budgets. Whether it’s the classic gear-driven approach, the smoother belt-driven experience, the hybrid solutions combining the best of both, or the cutting-edge Direct Drive technology, each option has its place in the realm of virtual racing. The key lies in understanding one’s priorities, budget constraints, and long-term commitment to the exhilarating world of sim racing.